Even robot systems occasionally need a negative supply voltage for some purpose or other, and in this kind of application in particular there is a need for an effective circuit that does not make greater demands then necessary in terms of current or space. If a low current 5 V supply is needed and only +5 V is available, a natural manufacturer to turn to is Maxim, and indeed in this case they do not let us down.The best known integrated circuit made by this company is the MAX232, a level shifter for serial ports with an integrated charge pump that does not need an external inductor.

Mini Power Inverter Project image:

Simple Mini Power Inverter

Along the same lines, although with a more stable output voltage and higher efficiency, is the MAX660. The device can ‘mirror’ any input voltage between 1.5 V and 5.5 V. With a 5 V input the output is typically –4.7 V with a load of 100 mA. Efficiency at 10 mA is around 96 % and at 100 mA is around 88 %. With an open-circuit output the IC draws a quiescent current of just 120 μA.There is little to say about the circuit itself.

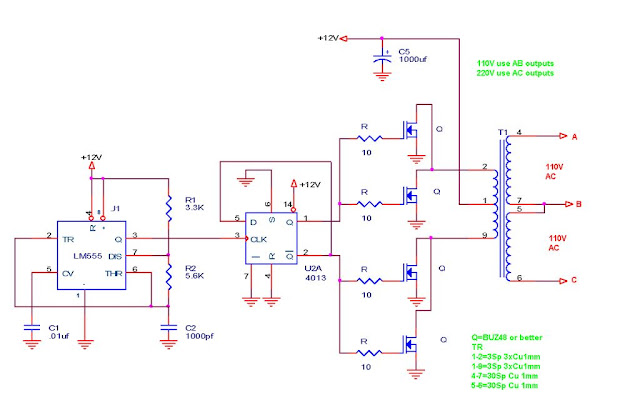

Mini Power Inverter Circuit diagram :

Simple Mini Power Inverter Circuit Diagram

The 0 Ω resistor on pin 1 selects the operating frequency. With R1 fitted, the circuit operates at 80 kHz; without it, at 10 kHz. The combination of L1 and C5 slightly reduces ripple on the output voltage; the choice of inductor is not as critical as it would be if it formed part of the switching circuit.Gerber files for the printed circuit board (which uses some SMD components) are available for download from the Elektor website, ref. 070279-11.zip. R1, C1 and C4 are 0603 SMDs and C3 is an SMD tantalum electrolytic capacitor. Either the MAX-660CSA or the MAX660M can be used; both come in SO8 packages. L1 is a 10 μH SMD inductor rated at 300 mA.

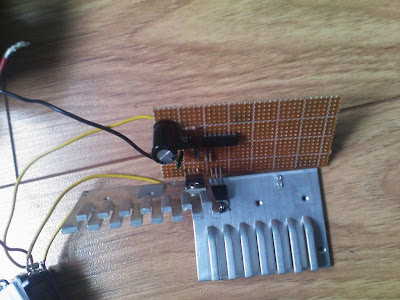

Detail:

Mini Power Inverter